[wheel size:1A 510x75x177.8 RZW 60 F 10 V29d]

[grinding method:surface grinding:wet]

[wheel speed:1842m/min]

[cutting depth:5μm]

[stock removal:0.3㎜]

[workpiece:hard chrome plating 600x400]

Workpiece is hard chrome plating. Conventional wheel caused loading and grinding sound cecame loudly with grinding 0.03mm. So, this wheel often needed dressing. However, Dolce can grind 0.1mm with no problem. Dolce is less- wearing andmakes grinding time short.

[wheel size:1A 760x75x304.8 RZW 80 E 60 10 V29d]

[grinding method:surface grinding:wet]

[wheel speed:1900m/min]

[cutting depth:10μm]

[stock removal:0.2mm]

[workpiece:hard chrome plating, SUS304, hastelloy]

[workpiece speed:13m/min]

This operation was difficult because of burning and scratches conventionally. However dolce causes few loading and burning.Therefore, this good grinding performance makes this operation easy. Moreover, dolce can grind SUS304 as well as plating.

[wheel size:7N 700x130x305 HWR 60 H 12 V29d]

[grinding method:surface grinding:wet]

[wheel speed:1778m/min]

[table feeding speed :40m/s]

[cutting depth:5μm]

[workpiece:cast iron 1200x900]

Ceramic wheel was used in the past. This wheel speed is 1319m/min, table feeding speed is 40m/s, cutting depth is 3μm. However, dolce provides good performance and fine roughness even if grinding condition becomes hard. Therefore, dolcemakes grinding time short.

[wheel size:1A 510x38x127 HWP 60 I 12 V29d]

[grinding method:cylindrical grinding:wet]

[wheel speed:800m/min]

[cuttingdepth:5μm]

[stock removal:0.4mm]

[surface roughness:less than 2S]

[workpiece:SUS304 Φ300x1000L]

The over wheel had been used for plating, but workpiece was changed to thermal spray ,aterial from plating. So, this conventional wheel often caused loading and this grinding performance became worse. However, dolce causes few loading and provides fine surface.

[wheel size:1A 915x100x304.8 RZW 100 F 10 V29d]

[grinding method:cylindrical grinding:wet]

[cutting depth:8μm]

[surfaceroughness:Ra0.8]

[workpiece:hastelloy C-276]

[workpiece speed:28.6m/min]

Conventional wheel often caused chattering. So, this wheel needed dressing many times and an operator could not leavegrinfing machine. However, dolce can grind to last finish grinding and causes no chattering with only first dressing. Moreover,the operator can leave grinding machine and can do other work. This is a great merit.

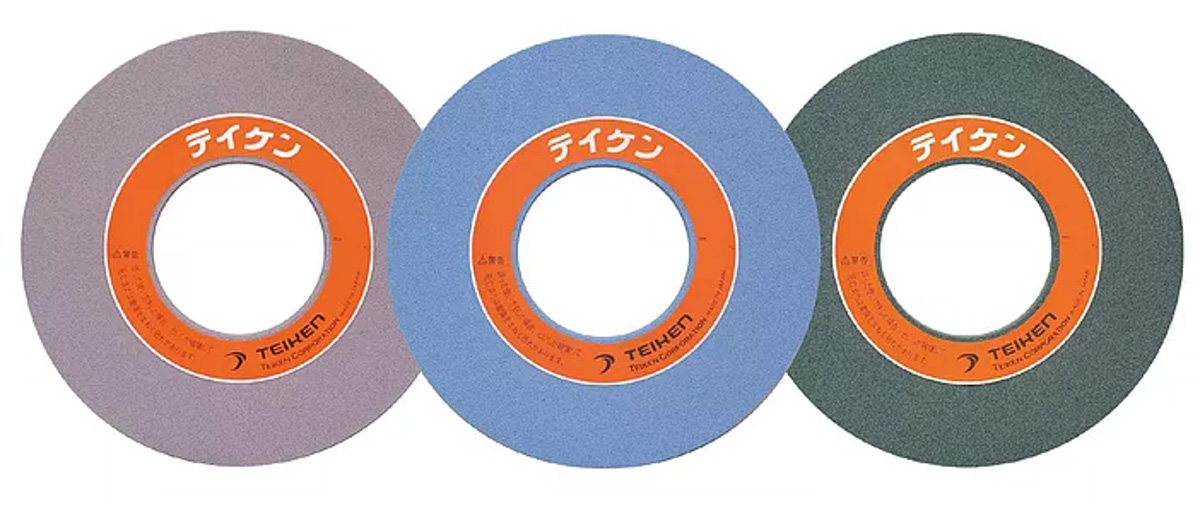

GRINDING WHEEL

They are characteristic

grinding wheels with "PoreTec"

DIAMOND/CBN WHEEL

We have vitrified bond wheels

which accumulate long-time technique

GRINDING RELATED PRODUCTS

We can make a proposal for

the total grinding process.