Production Process of TEIKEN Vitrified Bond Grinding Wheels.

Top quality of material to be ever had is used at all time.

Abrasive grain, bonding, stuff, chemical elements are stirred up until the blending attains its best optimum conditions that we expect provide the most desirable balance amongst porousness, starchiness, burability etc..., then we can be sure to supply the top flight quality of TEIKEN at all times.

We are preoared to produce a wide range of sizes, small of large to meet your request.

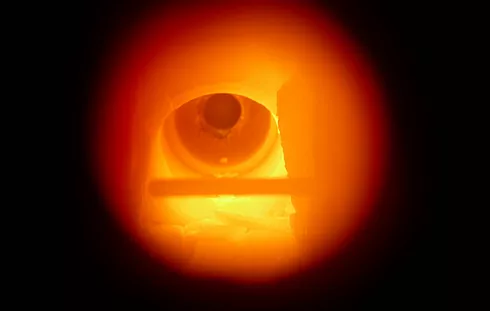

The molded objects are dried before baking process in the dehydration house making use of the heat from the kiln.

The semi-procesessed objiects stay in the kiln for a week at about 1300℃ max. following the optimized curve of firing temperture.

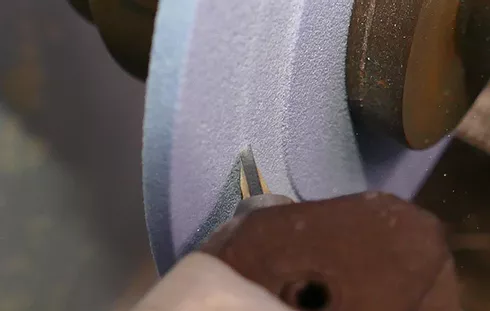

Those out of the kiln go to tool-machining with regular of diamond wheel into forms with dimensional accurcy the users may call for.

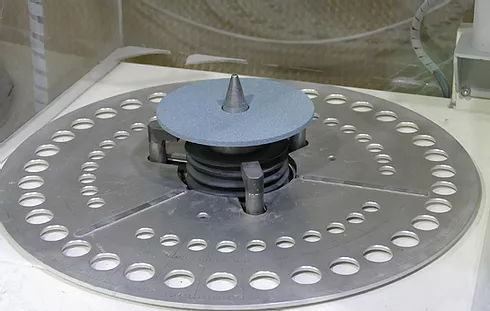

Every single piece of TEIKEN goes subjected to ultrasonic testing and auto-balance-checking test to keep the users free from hazardous cause by chance.

TEIKEN goods usually goes packed with recyclable bump-absorption stuff so hopefully no environmental contamination around.

GRINDING WHEEL

They are characteristic

grinding wheels with "PoreTec"

DIAMOND/CBN WHEEL

We have vitrified bond wheels

which accumulate long-time technique

GRINDING RELATED PRODUCTS

We can make a proposal for

the total grinding process.