●Few chip clogging

●Controll of size and volume of pores for

workpiece and grinding condition

●Few grinding burnings

●Good surface finish

[wheel size:1A 405*45*203.2 GC 80 HH 23 V4PO]

[grinding method:cylindlical grinding]

[workpiece material:urethane rubberroll]

reduction of grinding time thanks to decrease chip clogging and increase the stock removal

[wheel size:1A 610*75*304.8 GC 180 GG 34 V 4PO]

[grinding method:cylindrical grinding]

[workpiece material:paper roll and urethan(hardness:90°-95°]

3 kinds of grinding wheel(rough,medium and fine) are reduced 2 kinds of that(rough and fine) and grinding time is reduced.

[wheel size:1A 760*100*304.8 GC 80 GG 23 V4PO]

[grinding method:cylindlical grinding]

[workpiece material:urethane rubber,synthetic rubber]

Good efficiency thanks to decrease chip clogging and get stable surface.

[wheel size:1A 305*250*76.2 GC 80 HH 23 V 4PO]

[grinding method:cylindrical grinding]

[workpiece material:urethan and synthetic rubber]

Reduction of grinding time and good cutting performance thanks to decrease chip clogging

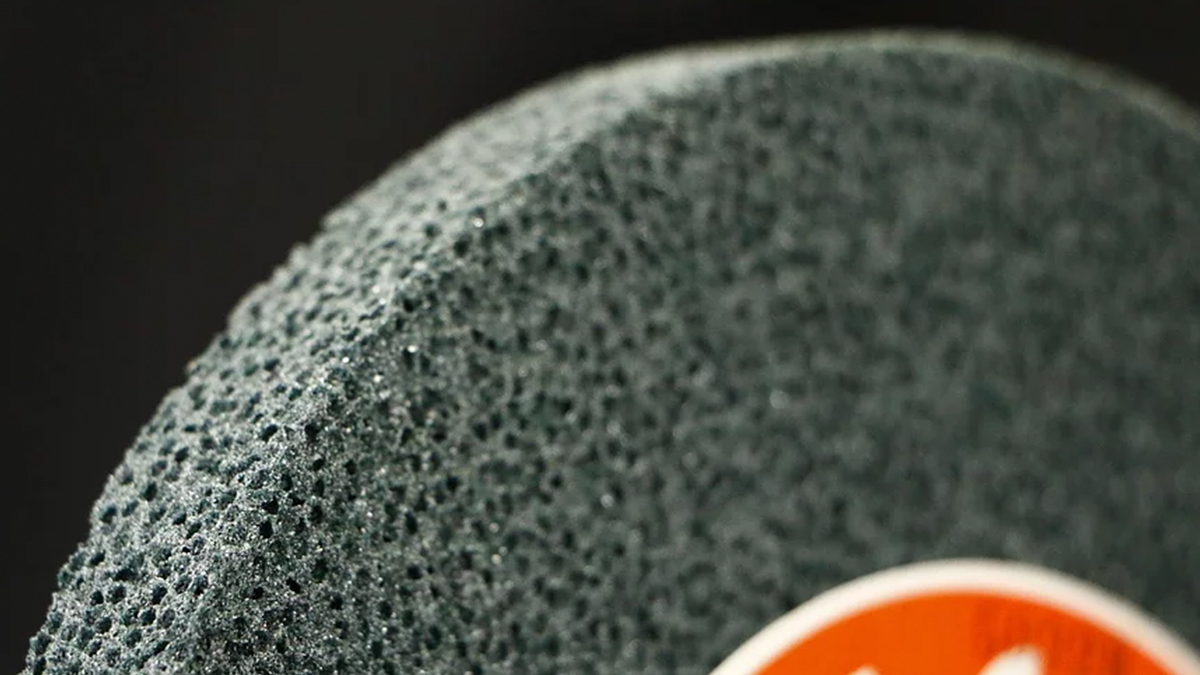

GRINDING WHEEL

They are characteristic

grinding wheels with "PoreTec"

DIAMOND/CBN WHEEL

We have vitrified bond wheels

which accumulate long-time technique

GRINDING RELATED PRODUCTS

We can make a proposal for

the total grinding process.